Views: 800 Author: Site Editor Publish Time: 2024-08-15 Origin: Site

CNC Boring Machine represents one of the transformative technologies that can be used to create a large variety of car parts or components from metals, plastics, and composite materials in the automobile industry. Here's how CNC boring machine finds its Application in the Automotive Industry.

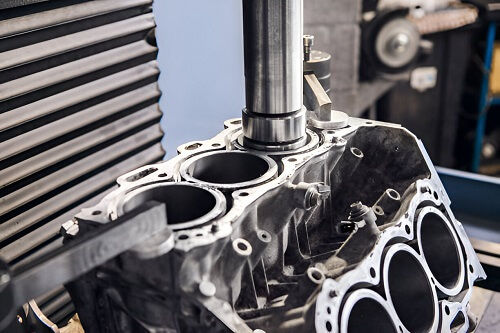

High-precision and intricate machining of key engine parts, which include cylinder heads, engine blocks, crankshafts, camshafts, pistons, valves, and connecting rods, are required, and all this is possible through the application of CNC technology. This ensures that all these components work at their best level of performance, remain durable, and are safe.

CNC boring machine is applied to the production of parts for transmissions, including gears and gearboxes, shafts, clutch elements. Indeed, all these components have to be manufactured with a high degree of accuracy to allow smooth, efficient transmission of power, smooth gear changing, and comfortable driving.

Key suspension and steering parts, like control arms, tie rods, ball joints, steering knuckles, and wheel hubs are impossible without CNC machining. These details are subjected to machining that requires great strength and accuracy in order to provide vehicle stability, controllability, and safety.

CNC boring machine finds applications in the manufacturing of brake components, such as calipers, rotors, brackets, and master cylinders. The accuracy in these components ensures safe, controlled, and consistent braking that contributes to improved vehicle safety and responsiveness.

CNC boring machine precision, versatility, and efficiency make it indispensable in the automotive sector. It supports the industry drive for quality, innovation, and superior vehicle performance.

If you are looking for high-quality CNC boring machine, Contact SmartekMech (smartekmech@gmail.com). We have a range of state-of-the-art CNC machine to help you produce automotive parts with the highest accuracy and precision.