Views: 1000 Author: Site Editor Publish Time: 2024-09-13 Origin: Site

Lathes and milling machines are essential in manufacturing. They shape materials into precise parts. But they work in different ways. Let's explore these equipment to help you choose the right one for your project. These machines are commonly found in machine shops and operate at high speed to ensure efficiency.

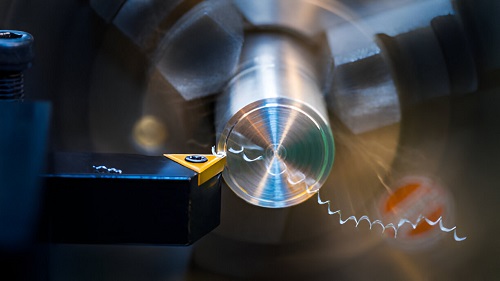

A lathe is a machine that rotates the workpiece. It uses stationary cutting tools and best for making round or cylindrical parts. The lathe operates at high speed to remove material from the workpiece efficiently, maintaining tight tolerances throughout the machining process.

Key features of lathes:

1. Rotating workpiece

2. Stationary cutting tools

3. Ideal for cylindrical parts

4. Can perform turning, facing and threading

5. Uses a tool holder for precise cutting

A milling machine uses rotating cutting tools. The workpiece stays still. Milling machines are great for flat surfaces and complex shapes. They are commonly used in machine shops to remove material from a workpiece with high precision.

Key features of milling machines:

1. Rotating cutting tools

2. Stationary workpiece

3. Good for flat surfaces and complex shapes

4. Can perform face milling, end milling, and drilling

5. Employs a tool holder for various cutting tools

Feature | Lathe | Milling Machine |

Workpiece Movement | The workpiece rotates | The workpiece stays still |

Tool Movement | Cutting tools move linearly | Cutting tools rotate and move in multiple axes |

Typical Parts Produced | Shafts, bolts, table legs, bowls | Flat surfaces, slots, gears, dies |

Precision | High precision for round parts | High precision for flat and complex shapes |

Both lathes and milling machines operate at high speed and are crucial in the machining process. They are designed to remove excess material while maintaining tight tolerances.

Use a lathe when:

1. Making cylindrical parts

2. Needing symmetrical shapes

3. Doing external or internal threading

4. Creating tapered surfaces

Common lathe operations:

Turning

Facing

Boring

Threading

Knurling

Use a milling machine when:

1. Creating flat surfaces

2. Cutting slots or grooves

3. Making complex 3D shapes

4. Needing precise holes or patterns

Common milling operations:

Face milling

End milling

Slot cutting

Drilling

Gear cutting

Feature | Lathe | Milling Machine |

Best for | Round parts | Flat and complex shapes |

Workpiece | Rotates | Stationary |

Cutting tool | Stationary | Rotates |

Precision | High for round parts | High for flat surfaces |

Versatility | Limited to round shapes | Wide range of shapes |

Speed | Fast for round parts | Varies with complexity |

Cost | Generally lower | Generally higher |

Consider these factors:

1. Shape of your parts

2. Material you're working with

3. Precision requirements

4. Production volume

5. Available space

6. Budget

7. Your skill level

8. Need for tight tolerances

Modern CNC machines operate at high speed and are common in machine shops. They excel at removing material from a workpiece with precision, often using sophisticated tool holders.

Modern machines often combine lathe and milling functions. These are called:

Mill-turn machines

Turn-mill centers

Multi-tasking machines

Benefits of multi-tasking machines:

1. Reduced setup time

2. Improved accuracy

3. Space-saving

4. Increased productivity

But they cost more and require more skill to operate.

Both lathes and milling machines now use CNC (Computer Numerical Control). CNC brings:

1. Increased precision

2. Better repeatability

3. Ability to make complex parts

4. Reduced human error

5. Improved ability to maintain tight tolerances

CNC has revolutionized how these machines operate. It allows for high-speed machining and removes excess material with great accuracy. The machining process is now more efficient than ever.

Lathe maintenance:

Regular lubrication

Checking belt tension

Cleaning chip buildup

Milling machine maintenance:

Tool sharpening

Alignment checks

Coolant management

Both need regular cleaning and calibration for best performance.

Lathe safety:

Secure workpiece firmly

Avoid loose clothing

Use proper speeds for material

Milling machine safety:

Use appropriate cutting speeds

Secure workpiece properly

Wear eye protection

Always follow manufacturer's safety guidelines for both machines.

Both lathes and milling machines are evolving:

1. Increased automation

2. Better integration with CAD/CAM software

3. Improved energy efficiency

4. Enhanced user interfaces

5. Integration of additive manufacturing (3D printing)

A: Not typically. Lathes are best for round parts. Some advanced lathes have milling capabilities, but they're limited compared to dedicated milling machines.

A: Generally, yes. Milling machines often have more axes of movement and more complex controls, which increases their cost.

A: Basic lathe operations are often considered easier to learn. Milling can be more complex due to multiple axes of movement.

Lathes and milling machines are both valuable tools. Lathes excel at round parts. Milling machines are best for flat surfaces and complex shapes. Your choice depends on your specific needs.

For many workshops, having both is ideal.SmartekMech provide lathe and milling machine combe, this gives you the flexibility to tackle a wide range of projects. Welcome to contact us (smartekmech@gmail.com).

content is empty!