Views: 1100 Author: Site Editor Publish Time: 2024-09-10 Origin: Site

Vertical CNC milling machines are changing modern manufacturing. They're essential in many industries.

These machines make products from medical devices to aerospace parts. They offer precision, speed, and versatility.

In this article, we'll explore why they're so important. We'll also see how they're changing production methods.

A vertical CNC milling machine is a smart tool. It uses computer control to cut materials.

CNC stands for Computer Numerical Control. This means a computer guides the cutting process. It's more precise and efficient than old manual machines.

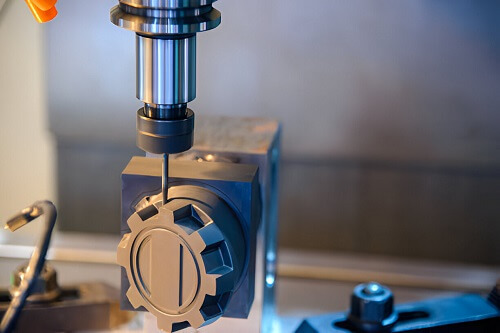

These machines work by rotating a cutting tool. The tool moves against a stationary workpiece. This process removes material to create the desired shape.

The 'vertical' part means the spindle axis is vertical. This is different from horizontal milling machines.

Vertical Spindle: The cutting tool points down. This helps remove chips and improves visibility. Chips fall away from the work area. This keeps the cutting zone clear.

Multi-Axis Movement: Many machines can move in 3, 4, or 5 directions. This allows for complex shapes. 3-axis machines move in X, Y, and Z directions. 4 and 5-axis machines can rotate the tool or workpiece. This enables more intricate designs.

Automated Tool Changers: Tools switch quickly. This saves time. The machine can use different tools for various cuts. It changes them automatically. This reduces manual intervention.

Advanced Controls: Easy-to-use software helps operate the machine. Operators can program complex cuts with user-friendly interfaces. Some systems use graphical interfaces. Others use conversational programming.

High-Speed Spindles: The cutting part can spin very fast. This works well for many materials. Speeds can reach up to 30,000 RPM or more. High speeds allow for faster cutting and better finishes.

Coolant Systems: These help manage heat during cutting. They can use liquid coolant or mist. This extends tool life and improves cut quality.

Rigid Construction: The machine's frame is strong and stable. This reduces vibration. It leads to more accurate cuts.

Vertical CNC mills are very accurate. They can make parts within 0.0001 inches of the design. This precision is crucial for industries like aerospace. It's also important for medical device manufacturing.

These machines maintain accuracy over long production runs. This consistency is hard to achieve with manual methods. It ensures that every part meets exact specifications.

CNC machines work faster than manual methods. A study shows they can cut production time by 70%. This helps companies meet deadlines and grow. They can produce more parts in less time.

One machine can often replace several manual operations. This streamlines the production process. It reduces the need for multiple setups. Faster production means quicker time-to-market for new products.

These machines cost a lot at first. But they save money over time. They need less labor. One operator can run multiple machines. This reduces labor costs.

They also waste less material. CNC mills can nest parts efficiently. This maximizes material use. They make fewer mistakes than manual methods. This means less scrap and rework.

Many companies see a return on investment within 12-18 months. The savings come from increased output and reduced waste.

Vertical CNC mills are useful in many fields. They can make:

Airplane parts: Engine components, structural elements

Car components: Engine blocks, transmission parts

Medical implants: Hip joints, dental implants

Energy equipment: Turbine blades, pump components

Defense products: Weapon components, armor plates

This versatility makes them valuable in diverse manufacturing settings. They can handle a wide range of materials and part sizes.

A: Vertical mills are better for certain tasks. They're good for face milling, drilling, and tapping. They also take up less floor space. This is good for small shops.

Horizontal mills are better for heavy cuts on large parts. They can support heavier workpieces. The choice depends on the specific job needs.

A: These machines can work with many materials:

Metals like aluminum, steel, and titanium

Plastics such as ABS, nylon, and acrylic

Composites including carbon fiber

Wood and wood products

Ceramics and glass

The right tools and settings are key for each material. Different cutting speeds and feed rates apply to different materials.

A: Modern machines use friendly software. It's easier to program them now. Some even have simple interfaces for those new to CNC.

CAM (Computer-Aided Manufacturing) software helps create toolpaths. Many systems offer simulation. This lets operators check the program before cutting. Some machines have conversational programming. This uses plain language commands.

AI and Machine Learning: Smart features help maintain machines and improve cutting. They can predict tool wear. Some systems adjust cutting parameters in real-time.

Better Sustainability: New machines use less energy and waste less material. Some use regenerative braking to save power. Others optimize tool paths to reduce material waste.

Hybrid Manufacturing: Some mills can now add material too, not just cut it away. They combine additive and subtractive processes. This opens up new design possibilities.

IoT Connectivity: Sensors help monitor machines in real-time. This leads to smarter factories. Operators can track performance from anywhere. It enables predictive maintenance.

Enhanced User Interfaces: Touch screens and gesture controls are becoming common. This makes operation more intuitive. It reduces training time for new operators.

Micromachining Capabilities: Some vertical CNC mills can now work on very small parts. This is useful in electronics and medical device manufacturing.

Vertical CNC milling machines are vital to modern manufacturing. They offer precision, efficiency, and versatility. These machines continue to evolve. They incorporate new technologies and capabilities.

For manufacturers, investing in CNC milling is crucial. It helps companies stay competitive in a global market. With SmartekMech Machine, businesses can boost productivity, quality, and innovation.

Contact SmartekMech (smartekmech@gmail.com) today and talk to us about your custom solution.

content is empty!