Views: 700 Author: Site Editor Publish Time: 2024-10-14 Origin: Site

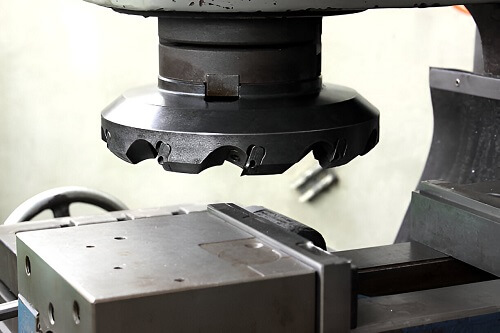

CNC gantry milling machine problems generally have: CNC gantry milling machine combination part can be divided into CNC gantry milling machine main body, CNC software and servo starting, and its problems are often in these places.

The following are common problems that may occur, when your equipment has these problems need to be dealt with in a timely manner. But if you need to replace or buy a new one, Yaogong is a very good choice.

Yaogong Equipment factory after rigorous testing, as well as we have 7x24 hours of after-sales service, so you can rest assured that use!

Fault Type | Subtype | Features |

Software Faults | System software | Built-in faults due to design |

Application software | Random faults due to human input errors | |

Hardware Faults | Permanent | Fixed faults that can't be fixed |

Intermittent | Random faults that can become permanent | |

Borderline | Faults due to aging parts, can become permanent | |

Interference Faults | Internal | Random faults from poor design or part changes |

External | Random faults from work environment | |

Servo Faults | Control part | Faults from overload or poor cooling |

Drive motor | Faults from dirt, rust, wear, or burnout | |

Mechanical Wear | - | Wear from friction and chemical damage |

We need to check and maintain the wire rope every week, lubricate the wire rope and wire rope pulley and rotating bearing with grease.

You also need to check the wire rope for corrosion, wear or wire strand breakage, and replace the wire strand as soon as it is found to be broken.

Monthly internal inspection of the control electric cabinet and suspension operating box should be carried out to dust them. In addition, the filters of the electric cabinet fans are to be cleaned at least once a month.

Once a month you need to check the smoothness of the sliding surface, whether the oil groove is smooth, whether the oil moistening is sufficient, whether the gap between the wedge iron and the guide rail is moderate, and whether the lower end face is whole. If there is a problem, it should be dealt with in time.

Every six months to check the lubricating oil tank, check whether the oil quality is in line with the requirements, whether the oil quantity is in place, the box to ensure that the clean no dirt, the oil window should be clear, no leakage, once the problem is found, please deal with it in time.

The above is the CNC gantry milling machine for regular maintenance of the place, I hope the above knowledge will help you.